Industrial Water and Wastewater Treatment Business

We supply industrial fields with systems that

reduce both costs and environmental impacts.

Industry has a wide range of water related needs, such as securing water quality levels appropriate for the purposes for which the water will be used, environmentally friendly wastewater treatment, cost reductions, and facility size reductions. SUIDO KIKO uses many leading edge technologies to satisfy these needs and contribute to improved customer competitiveness.

At the Kansai Electric Power Maizuru Power Station,

our desalination plant processes 4,400㎥/day.

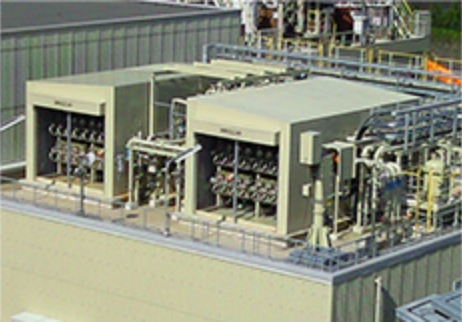

The Maizuru Power Station (a coal-fired power station), uses a seawater desalination plant supplied by SUIDO KIKO. This plant uses two-layer filtration apparatus and polishing filtration apparatus to remove foreign substances from seawater, producing cooling water desalinated via seawater RO.

-

Two-layer filtration apparatus

Before desalination processing, chemical dosing is performed, and flocculation filtration is used to remove impurities from the seawater.

-

Polishing filtration

apparatusFine foreign materials in the seawater are removed via secondary filtration

(polishing filtration). -

Reverse Osmosis

Membrane FiltrationThe seawater is pressurized and passed through an RO membrane(reverse osmosis membrane)module, separating it into desalinated water and high salinity seawater.

Maizuru Power Station

Two-layer filtration apparatus / polishing filtration apparatus(11,520㎥/day)

SWRO facility(4,400㎥/day)

We respond to the differing needs of individual industrial

fields, providing the water they require.

Chemical plant activated carbon/UF facility(600㎥/day)Drinking water is supplied to the plant from industrial water.

Automobile factory RO facility (720㎥/day)Industrial water is supplied to the plant from well water.

We provide treatment methods optimized to the individual

characteristics of industrial wastewater.

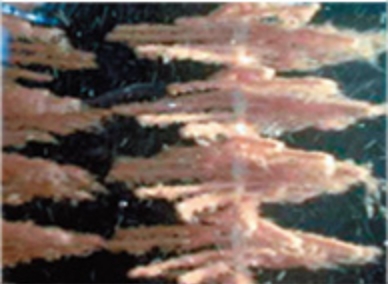

Industrial wastewater has a diverse range of characteristics. In our wastewater treatment, we combine physical, chemical, and biological approaches, such as Biofringe, which uses food chains to dramatically reduce sludge production, to produce optimal results. We have an extensive track record, including supplying a paper manufacturing factory with some of the world’s largest thickeners (devices for separating solid particles in liquids).

75m diameter thickeners, some of the largest in the world.

Biofringe uses biological filters to reduce sludge production through food chain action.

Contact :